Technology

Overview

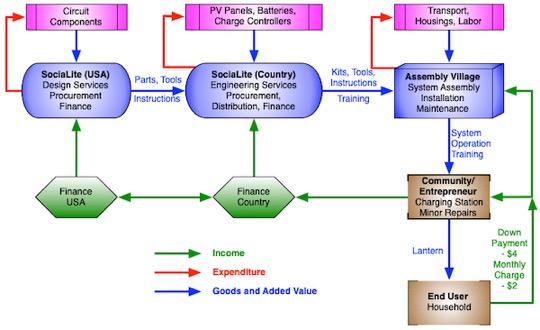

Working with our advisors and community groups in which the end-user assumes responsibility for system implementation comes the promise of self-sustainability—an approach fundamentally different to many organizations. Characteristics common to many of these ventures include light sources developed and manufactured far from the place of use; local infrastructures for the maintenance and repair of these systems do not exist and cannot be created; equipment often sold at less than cost price with subsidies from unsustainable sources; systems that are otherwise unaffordable to those for whom they are intended—the extreme poor.

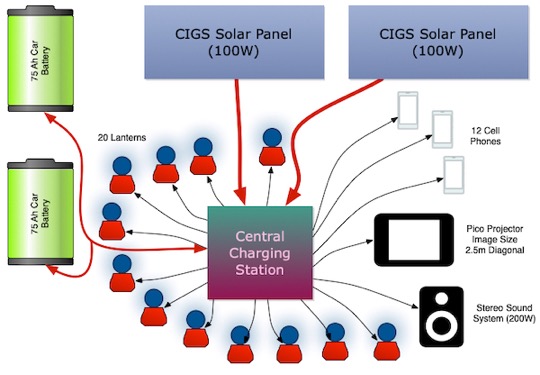

Our prototype system has evolved into a versatile community pico-grid supplied as a self-contained kit—a lighting system in a suitcase that includes the necessary tools, instructions in local languages, lantern and grid components, audio amplifier and pico projector. Add locally sourced lantern housing materials and batteries to provide a complete system ready for delivery—on a pick up truck, a bicycle or someone’s head—a functional manufacturing and supply chain.

The Lantern

Initial designs for the circuitry were simple, comprehendible by those with a high school diploma, but inefficient with separate circuitry for the LED and battery charging functions. A microprocessor gave us a single, firmware field upgradable, board with required functionality yielding a lantern that works indefinitely in the deep bush. Through hole circuitry provides a board that can be assembled by those unfamiliar with a transistor or a LED enabling the end-user to be more directly connected to the technology, through self-assembly and repair. Powered by 4.5 Ah, 6V lead acid batteries, the lanterns run at full power for about 40 hrs (reduced power for about 120 hrs) so requiring a weekly recharge and enabling each outlet to support up to 7 lanterns.

Operation

Our current model is the provision of a lighting service in which users pay for use of the lanterns—not precluding an entrepreneur purchasing a complete system outright. Choosing to work with the most marginalized communities on the planet—those who now fall out of the remit of the large philanthropic and UN agencies, the forgotten communities of 2020, poses a challenge. Someone, somewhere has to purchase the equipment and the end-user has to pay the real price—with a subsidized or zero rate of interest. Upon introduction of SociaLite to a community, users pay a deposit (≈ 2USD) on acquisition of a lantern to join a "lighting club", followed by a monthly charging fee (≈ 0.5USD)—both adjusted to match community assets. Extra income is derived from the per use payment for cell phone charging and use of the audiovisual entertainment facilities—both streams paying off the capital cost of system installation, operation (including lantern battery replacement and recycling) and maintenance—the excess being used to purchase the equipment for succeeding communities.

With bulk purchase, the cost of a lantern approaches 10USD—allowing compensation for those who assemble, install and operate the system. The cost of PV panels has dropped to ≈1USD/watt peak for rigid panels; robust lead acid batteries (75Ah) run to about 150USD in country. With audiovisual facilities, the cost of a typical installed pico-grid is approximately 1500USD.